X-ray reflectometry is a technique that uses the way X-ray’s reflect from flat, layered samples to obtain information about the thickness, composition (‘electron density’) and roughness of thin films and other flat layered structure with layer thicknesses of 2-200 nm. In this method, a sample is illuminated by monochromatic X-rays and the reflected X-rays are detected to obtain the fraction of X-rays reflected. One measures the fraction of reflected X-rays as a function of the incoming angle (θ < 5°) of the X-rays to obtain a reflectogram. The measured reflectivity of X-rays depends on the wavelength λ and incident angle θ. As illustrated in Fig. 1, for incident angles smaller than the critical angle, all X-rays are reflected. For larger angles, the reflectivity of a material decreases rapidly with increasing angle of incidence. Instead of expressing the reflectivity as a function of the incident angle and/or wavelength, it is typically expressed as a function of the momentum transfer Q of the neutron when reflected by the sample: The momentum transfer incorporates the effect of the incident angle and wavelength in a singly quantity and is related to the angle of incidence and wavelength through.

Analogous to the reflection of optical light from surfaces, the critical angle and the subsequent decay of reflectivity with increasing angle of incidence depend on the index of refraction of the material studied. The higher the electron density of the material, the higher the critical angle.

Constructive/destructive interference may occur when a layer of a material is deposited on top of a substrate composed of a material with a different electron density. In this case, interference may occur between the X-rays reflected from the surface of the sample and X-rays reflected from the interface of the two materials. This interference results in so-called fringes in the reflectivity pattern, whereby the width of the fringes is related to the thickness of the layer and the amplitude to the difference in electron density of the two materials.

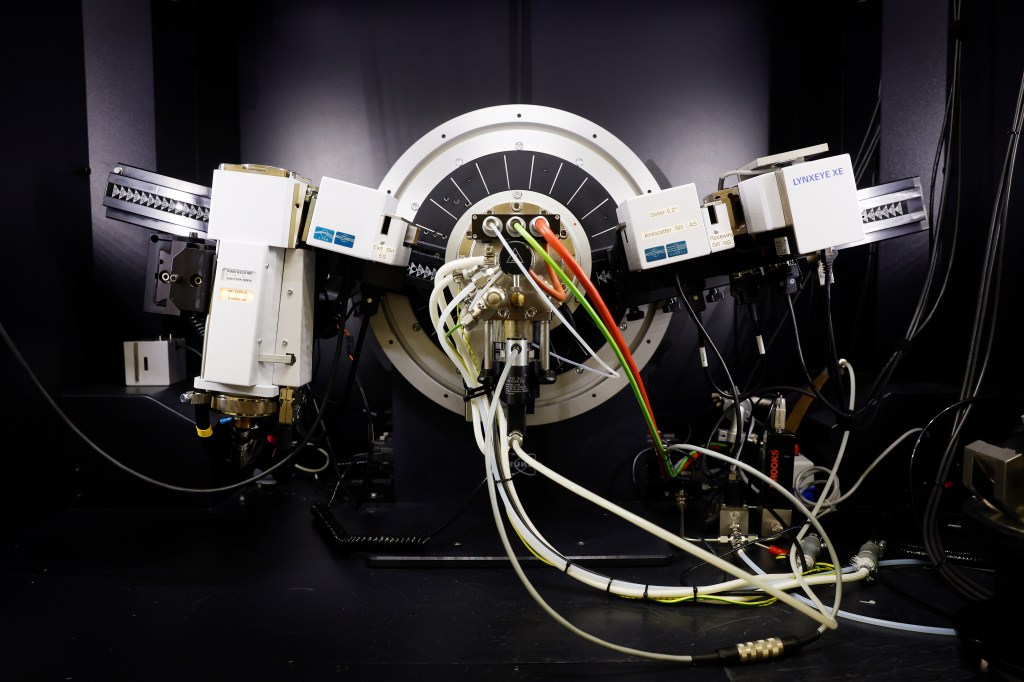

For our research we often use the Bruker D8 Discover twin-twin diffractometer of the Department of Chemical Engineer of TU Delft to perform XRR measurements. The diffractometer (Cu anode) is equipped on the primary side with a focussing mirror and a fixed slit to determine the footprint on the sample. On the secondary side, we typically use two slits to further collimate the beam and tune the resolution. The detector is operated in 0D mode to deal with the high count rates. In an XRR measurement, we synchronously alter the two arms of the diffractometer to measure the fraction of X-rays as a function of incoming the reflected angle. The sample itself can be located in air as well as inside an Anton Paar XRK 900 Reactor chamber. This allows complete control of the environment in terms of temperature (up to 900 °C) and gas (0-10 bar of various gas (mixtures)).