X-ray diffraction is a technique that can be used to study how atoms are organized inside a material. It relies on the fact that crystalize materials interact with X-rays in such a way that a beam of X-rays are diffracted into specific directions. The specific angles and intensity of such a diffracted beam, summarized in a diffraction pattern, provide information on the crystal structure of a material.

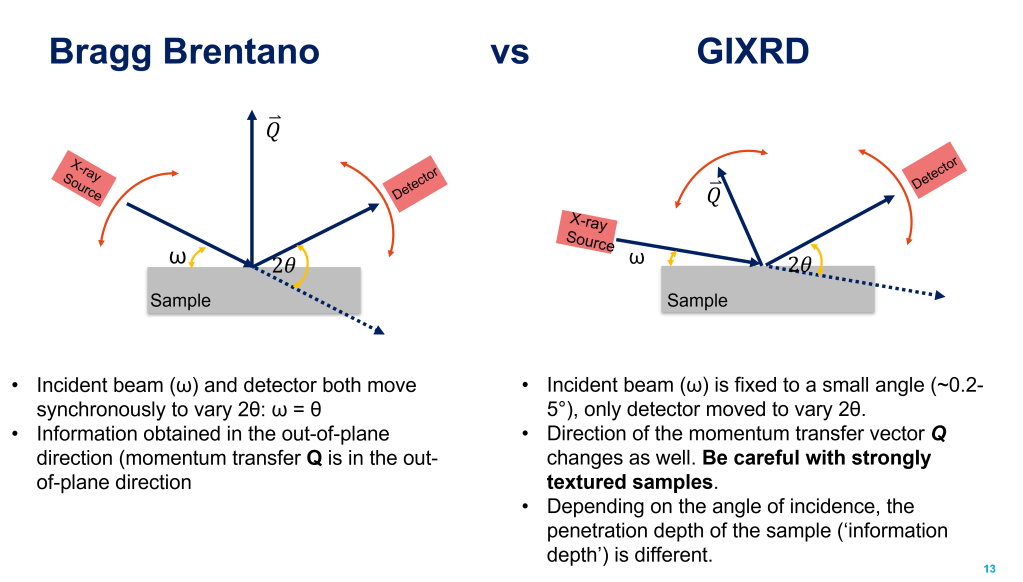

For our research we often use the Bruker D8 Discover twin-twin diffractometer located at the Department of Chemical Engineer of TU Delft. This diffractometer uses a Cu anode to generate X-rays and a 1D detector (can be operated as 0D) to detected them and features and Euclidian cradle as standard sample stage. The diffractometer is equipped on the primary side with either a focussing mirror or a motorized slit box and has the additional option to insert a fixed slit. On the secondary side, it features an axial Soller slit or a variable slit box as well as the possibility to insert a fixed slit. This flexibility allows us to perform Bragg-Brentano X-ray Diffraction (theta-2theta scans), Grazing-Incidence, X-ray Reflectometry and In-Plane X-ray diffraction with the same set-up.

In addition, we have an Anton Paar XRK 900 Reactor chamber that we can mount on the sample position. This chamber allows Bragg-Brentano, GIXRD and XRR measurements in a temperature controlled environment of up to 900 °C. On top of that, we can vary the gas atmosphere inside the XRK using a dedicated setup between 0-10 bar which allows us to (automatically) expose our samples to e.g. varying (partial) hydrogen pressures/concentrations.

Furthermore, we make use of the Panalytical X’pert diffractometer and the Anton Paar TTK450 chamber located at the Department of Radiation Science and Technology to study the structural response of our materials down to -200 °C while exposing it to various pressures of a hydrogen containing gas (0-1 bar).