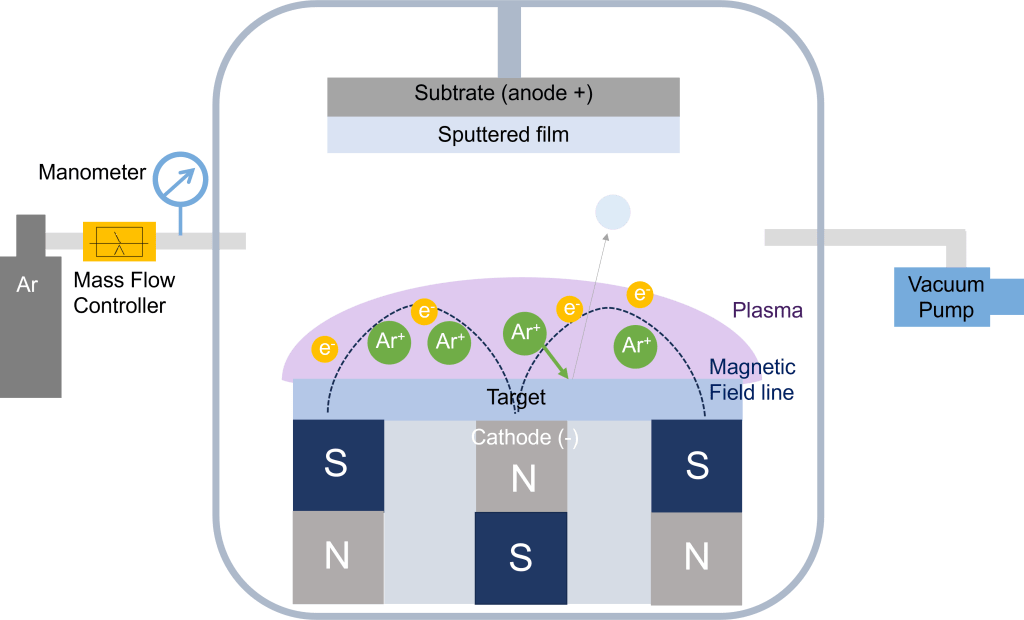

All our research starts with a good sample. Most of our samples are made using physical vapor deposition (PVD)/magnetron sputtering. A magnetron sputtering set-up consists of a big vacuum chamber in which disks of target materials are located. The samples (substrate or optical fibers) that are to be sputtered are located above these targets. During deposition a low pressure of an inert gas (‘sputtering gas’) is realized in the chamber to create a plasma. This plasma is created by applying a high voltage between the cathode (located behind the target) and the anode (the wall of the chamber/ground/substrate). This causes electrons present in the sputtering gas to be accelerated away from the target and collide with the molecules in the gas. As a result, electrons are knocked of the sputtering gas creating ions. Magnets ensure that the electrons are confined to the space just above the target ensuring a sufficiently high density plasma. As a result, the target is bombarded with high-energy ions, which causes atoms to be liberated from the target. These atoms can then travel to the surface that is to be sputtered to create a film. By controlling the sputtering time, gas pressure and the power applied during deposition highly controlled and reproducible depositions can be made. In addition, by simultaneously sputtering targets at well-defined powers one can create quite precise alloy compositions. As no solvents are used during deposition, it is a relatively environmentally benign method to deposit materials.

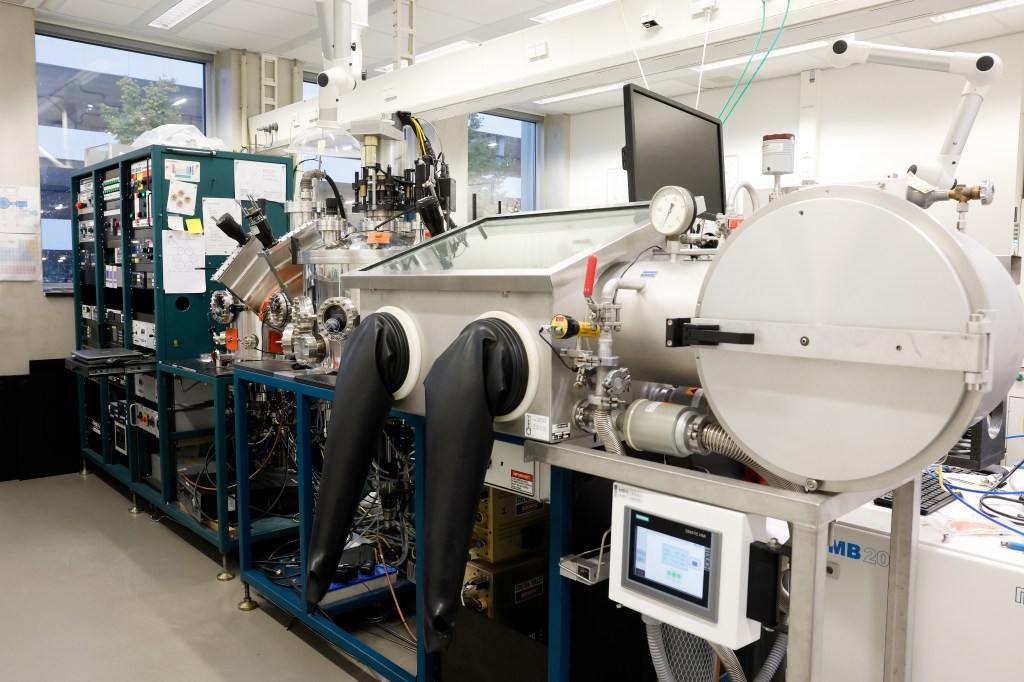

Our depositions are performed on the PVD set-up of the MECS group of the Department of Chemical Engineering. These depositions can be performed on substrates (up to 3’’ in diameter) or on the tip or side of optical fibers to create real sensors. The set-up (AJA int.) contains two deposition chamber allowing the simultaneous installation of 4 and 6 sputter targets. These can be metals, insulators or polymers, and for the latter two radiofrequency (r.f.) magneton sputtering is typically used to avoid charge-buildup near the target. The set-up is connected to a glovebox allowing the handling of air-sensitive samples. Differently, gas can also be added to the deposition chamber to perform reactive sputtering, allowing one for example to create (oxy)hydride films. The substrates/fibers are typically rotated during deposition to enhance the homogeneity of the layers. Differently, one can also make gradient thickness/composition films by not performing such rotation and accurately setting the rates and tilt of the sputter guns.